How to Cut a Gear on a Lathe

Center lathe with digital read out and chuck baby-sit. Size is 460 mm bore x chiliad mm between centers

A metallic lathe or metalworking lathe is a big class of lathes designed for precisely machining relatively hard materials. They were originally designed to motorcar metals; withal, with the advent of plastics and other materials, and with their inherent versatility, they are used in a broad range of applications, and a wide range of materials. In machining jargon, where the larger context is already understood, they are usually simply called lathes, or else referred to by more than-specific subtype names (toolroom lathe, turret lathe, etc.). These rigid machine tools remove material from a rotating workpiece via the (typically linear) movements of various cutting tools, such as tool bits and drill bits.

Construction [edit]

The pattern of lathes can vary greatly depending on the intended application; however, bones features are mutual to most types. These machines consist of (at the least) a headstock, bed, carriage, and tailstock. Better machines are solidly constructed with wide bearing surfaces (slide-ways) for stability, and manufactured with great precision. This helps ensure the components manufactured on the machines can meet the required tolerances and repeatability.

Headstock [edit]

Headstock with legend, numbers and text within the description refer to those in the epitome

The headstock (H1) houses the main spindle (H4), speed change mechanism (H2, H3), and change gears (H10). The headstock is required to be made every bit robust as possible due to the cut forces involved, which can distort a lightly built housing, and induce harmonic vibrations that will transfer through to the workpiece, reducing the quality of the finished workpiece.

The main spindle is generally hollow to allow long confined to extend through to the work expanse. This reduces preparation and waste of material. The spindle runs in precision bearings and is fitted with some means of attaching workholding devices such equally chucks or faceplates. This cease of the spindle usually as well has an included taper, often a Morse taper, to allow the insertion of hollow tubular (Morse standard) tapers to reduce the size of the tapered hole, and permit use of centers. On older machines ('50s) the spindle was directly driven past a flat belt pulley with lower speeds available past manipulating the bull gear. Later machines use a gear box driven by a dedicated electric motor. A fully 'geared head' allows the operator to select suitable speeds entirely through the gearbox.

Beds [edit]

The bed is a robust base that connects to the headstock and permits the carriage and tailstock to be moved parallel with the axis of the spindle. This is facilitated past hardened and ground bedways which restrain the carriage and tailstock in a prepare track. The carriage travels by ways of a rack and pinion arrangement. The leadscrew of authentic pitch, drives the carriage holding the cutting tool via a gearbox driven from the headstock.

Types of beds include inverted "V" beds, apartment beds, and combination "V" and flat beds. "Five" and combination beds are used for precision and lite duty work, while flat beds are used for heavy duty work.[ citation needed ]

When a lathe is installed, the first stride is to level it, which refers to making certain the bed is not twisted or bowed. There is no need to make the machine exactly horizontal, but it must exist entirely untwisted to achieve accurate cutting geometry. A precision level is a useful tool for identifying and removing any twist. It is advisable also to employ such a level along the bed to discover bending, in the example of a lathe with more than four mounting points. In both instances the level is used every bit a comparator rather than an accented reference.

Feed and atomic number 82 screws [edit]

The feedscrew (H8) is a long driveshaft that allows a series of gears to drive the carriage mechanisms. These gears are located in the apron of the carriage. Both the feedscrew and leadscrew (H7) are driven by either the alter gears (on the quadrant) or an intermediate gearbox known as a quick alter gearbox (H6) or Norton gearbox. These intermediate gears allow the correct ratio and direction to exist ready for cutting threads or worm gears. Tumbler gears (operated by H5) are provided betwixt the spindle and gear railroad train along with a quadrant plate that enables a gear train of the correct ratio and management to be introduced. This provides a constant relationship between the number of turns the spindle makes, to the number of turns the leadscrew makes. This ratio allows screwthreads to exist cutting on the workpiece without the aid of a die.

Some lathes accept but one leadscrew that serves all wagon-moving purposes. For screw cutting, a half nut is engaged to exist driven by the leadscrew's thread; and for full general ability feed, a primal engages with a keyway cut into the leadscrew to drive a pinion forth a rack that is mounted along the lathe bed.

The leadscrew will be manufactured to either majestic or metric standards and volition crave a conversion ratio to exist introduced to create thread forms from a unlike family. To accurately convert from one thread form to the other requires a 127-tooth gear, or on lathes not large enough to mount one, an approximation may be used. Multiples of 3 and 7 giving a ratio of 63:1 tin can be used to cut fairly loose threads. This conversion ratio is often congenital into the quick change gearboxes.

The precise ratio required to catechumen a lathe with an Imperial (inch) leadscrew to metric (millimeter) threading is 100 / 127 = 0.7874... . The all-time approximation with the fewest total teeth is very often 37 / 47 = 0.7872... . This transposition gives a constant -0.020 percent error over all customary and model-maker's metric pitches (0.25, 0.thirty, 0.35, 0.40, 0.45, 0.l, 0.60, 0.70, 0.75, 0.lxxx, 1.00, 1.25, 1.fifty, i.75, 2.00, 2.50, iii.00, three.50, 4.00, four.50, 5.00, 5.50 and 6.00 mm).

Carriage [edit]

The parts of a lathe carriage:

- Toolpost

- Chemical compound/top-slide

- Cantankerous-slide

- Saddle

- Apron

See text for more details.

In its simplest grade the carriage holds the tool scrap and moves it longitudinally (turning) or perpendicularly (facing) nether the control of the operator. The operator moves the carriage manually via the handwheel (5a) or automatically by engaging the feed shaft with the carriage feed machinery (5c). This provides some relief for the operator as the motility of the carriage becomes power assisted. The handwheels (2a, 3b, 5a) on the carriage and its related slides are usually calibrated, both for ease of utilise and to assist in making reproducible cuts. The carriage typically comprises a top casting, known every bit the saddle (4), and a side casting, known as the apron (five).

Cross-slide [edit]

The cross-slide (3) rides on the carriage and has a feedscrew which travels at right angles to the main spindle axis. This permits facing operations to exist performed, and the depth of cut to be adjusted. This feedscrew can be engaged, through a gear train, to the feed shaft (mentioned previously) to provide automated 'ability feed' motion to the cantankerous-slide. On almost lathes, but i direction can be engaged at a time every bit an interlock mechanism will close out the second gear train.

Cross-slide handwheels are unremarkably marked in terms of the part'due south bore, so one graduation representing .001 inches of bore corresponds to .0005 inches of cross-slide motility.

Compound rest [edit]

The compound rest (or meridian slide) (2) is normally where the tool post is mounted. It provides a smaller amount of movement (less than the cross-slide) along its axis via another feedscrew. The compound remainder axis tin exist adapted independently of the carriage or cross-slide. It is used for turning tapers, to control depth of cut when screwcutting or precision facing, or to obtain finer feeds (nether manual control) than the feed shaft permits. Normally, the compound residuum has a protractor marked in its base (2b), enabling the operator to suit its axis to precise angles.

The slide residuum (as the earliest forms of carriage were known) can be traced to the fifteenth century. In 1718 the tool-supporting slide rest with a set of gears was introduced by a Russian inventor Andrey Nartov and had limited usage in the Russian industry.[1]

The first fully documented, all-metal slide rest lathe was invented by Jacques de Vaucanson around 1751. It was described in the Encyclopédie a long time before Maudslay invented and perfected his version. It is likely that Maudslay was not aware of Vaucanson's work, since his commencement versions of the slide rest had many errors that were not nowadays in the Vaucanson lathe.

In the eighteenth century the slide balance was as well used on French ornamental turning lathes.

The suite of gun boring mills at the Purple Arsenal, Woolwich, in the 1780s by the Verbruggan family also had slide rests. The story has long circulated that Henry Maudslay invented it, but he did not (and never claimed so). The fable that Maudslay invented the slide rest originated with James Nasmyth, who wrote ambiguously about it in his Remarks on the Introduction of the Slide Principle, 1841;[2] later writers misunderstood, and propagated the error. However, Maudslay did assistance to disseminate the idea widely. It is highly probable that he saw it when he was working at the Arsenal as a boy. In 1794, whilst he was working for Joseph Bramah, he made ane, and when he had his own workshop used it extensively in the lathes he fabricated and sold there. Coupled with the network of engineers he trained, this ensured the slide residue became widely known and copied past other lathe makers, and then diffused throughout British technology workshops. A practical and versatile screw-cutting lathe incorporating the trio of leadscrew, change gears, and slide rest was Maudslay's most important achievement.

Toolpost [edit]

The tool bit is mounted in the toolpost (i) which may be of the American lantern style, traditional four-sided square mode, or a quick-change style such as the multi-set organisation pictured. The advantage of a quick alter set up-upwardly is to permit an unlimited number of tools to exist used (up to the number of holders available) rather than being express to one tool with the lantern style, or to 4 tools with the iv-sided type. Interchangeable tool holders permit all tools to be preset to a heart height that does not change, even if the holder is removed from the motorcar.

Tailstock [edit]

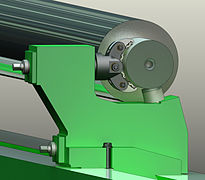

Tailstock with legend, numbers and text within the description refer to those in the epitome

The tailstock is a tool (drill), and middle mount, reverse the headstock. The spindle (T5) does not rotate simply does travel longitudinally under the action of a leadscrew and handwheel (T1). The spindle includes a taper to concur drill bits, centers and other tooling. The tailstock can exist positioned forth the bed and clamped (T6) in position every bit dictated past the piece of work piece. There is also provision to starting time the tailstock (T4) from the spindles axis, this is useful for turning small tapers, and when re-aligning the tailstock to the axis of the bed.

The prototype shows a reduction gear box (T2) between the handwheel and spindle, where big drills may necessitate the actress leverage. The tool chip is normally made of HSS, cobalt steel or carbide.

Steady, follower and other rests [edit]

Long workpieces often demand to exist supported in the middle, as cutting tools tin push (bend) the work piece abroad from where the centers tin can support them, because cut metallic produces tremendous forces that tend to vibrate or fifty-fifty bend the workpiece. This extra back up can be provided by a steady rest (besides called a steady, a fixed steady, a eye balance, or sometimes, confusingly, a middle). Information technology stands stationary from a rigid mounting on the bed, and it supports the workpiece at the rest'south heart, typically with three contact points 120° apart. A follower rest (also called a follower or a travelling steady) is like, simply it is mounted to the carriage rather than the bed, which means that as the tool bit moves, the follower balance "follows along" (because they are both rigidly connected to the same moving carriage).[3]

Follower rests tin can provide support that direct counteracts the springing force of the tool scrap, right at the region of the workpiece being cut at any moment. In this respect they are coordinating to a box tool. Any rest transfers some workpiece geometry errors from base (bearing surface) to processing surface. It depends on the rest design. For minimum transfer rate correcting rests are used. Rest rollers typically cause some additional geometry errors on the processing surface.

-

-

-

Correcting rest for precision grinding or turning

-

Correcting rest piece of work video

Types of metal lathes [edit]

In that location are many variants of lathes inside the metalworking field. Some variations are not all that obvious, and others are more a niche area. For case, a centering lathe is a dual head machine where the piece of work remains fixed and the heads motility towards the workpiece and car a heart drill hole into each end. The resulting workpiece may then be used "betwixt centers" in another functioning. The usage of the term metal lathe may also be considered somewhat outdated these days. Plastics and other blended materials are in wide utilise and, with appropriate modifications, the same principles and techniques may be applied to their machining every bit that used for metal.

Center lathe / engine lathe / bench lathe [edit]

The terms center lathe, engine lathe, and bench lathe all refer to a basic type of lathe that may be considered the archetypical class of metalworking lathe most often used past the general machinist or machining hobbyist. The name bench lathe implies a version of this class small-scale plenty to be mounted on a workbench (but even so full-featured, and larger than mini-lathes or micro-lathes). The construction of a center lathe is detailed higher up, but depending on the year of manufacture, size, cost range or desired features, even these lathes tin can vary widely between models.

Engine lathe is the name applied to a traditional late-19th-century or 20th-century lathe with automatic feed to the cut tool, as opposed to early lathes which were used with manus-held tools, or lathes with transmission feed but. The usage of "engine" here is in the mechanical-device sense, non the prime number-mover sense, as in the steam engines which were the standard industrial power source for many years. The works would have one large steam engine which would provide power to all the machines via a line shaft system of belts. Therefore, early on engine lathes were generally 'cone heads', in that the spindle unremarkably had attached to it a multi-step caster chosen a cone caster designed to have a flat belt. Dissimilar spindle speeds could be obtained by moving the flat belt to different steps on the cone pulley. Cone-head lathes usually had a countershaft (layshaft) on the dorsum side of the cone which could be engaged to provide a lower fix of speeds than was obtainable by direct belt drive. These gears were called dorsum gears. Larger lathes sometimes had ii-speed back gears which could be shifted to provide a notwithstanding lower gear up of speeds.

When electric motors started to get common in the early 20th century, many cone-head lathes were converted to electrical power. At the same time the state of the art in gear and bearing practise was advancing to the point that manufacturers began to make fully geared headstocks, using gearboxes analogous to automobile transmissions to obtain diverse spindle speeds and feed rates while transmitting the higher amounts of power needed to accept full reward of high-speed steel tools. Cutting tools evolved again, with the introduction of man-made carbides, and became widely introduced to full general manufacture in the 1970s. Early carbides were attached to toolholders by brazing them into a machined 'nest' in the tool holders. Later designs allowed tips to be replaceable and multi faceted, allowing them to exist reused. Carbides tolerate much college machining speeds without wearing. This has led to machining times shortening, and therefore production growing. The demand for faster and more powerful lathes controlled the direction of lathe evolution.

The availability of inexpensive electronics has once more changed the way speed command may be applied by assuasive continuously variable motor speed from the maximum downward to almost nix RPM. This had been tried in the late 19th century but was non plant satisfactory at the time. Subsequent improvements in electric circuitry have made it viable again.

Toolroom lathe [edit]

A toolroom lathe is a lathe optimized for toolroom piece of work. It is substantially merely a pinnacle-of-the-line heart lathe, with all of the best optional features that may be omitted from less expensive models, such equally a collet closer, taper attachment, and others. The bed of a toolroom lathe is more often than not wider than that of a standard heart lathe. There has also been an implication over the years of selective assembly and extra plumbing equipment, with every intendance taken in the building of a toolroom model to brand information technology the smoothest-running, most-accurate version of the machine that tin can be built. However, inside one brand, the quality difference between a regular model and its corresponding toolroom model depends on the architect and in some cases has been partly marketing psychology. For proper noun-brand machine tool builders who made just high-quality tools, there wasn't necessarily any lack of quality in the base of operations-model product for the "luxury model" to meliorate upon. In other cases, especially when comparing dissimilar brands, the quality differential betwixt (1) an entry-level center lathe built to compete on price, and (ii) a toolroom lathe meant to compete only on quality and non on price, can be objectively demonstrated by measuring TIR, vibration, etc. In any case, because of their fully ticked-off selection list and (real or implied) higher quality, toolroom lathes are more than expensive than entry-level center lathes.

Turret lathe and capstan lathe [edit]

Turret lathes and capstan lathes are members of a class of lathes that are used for repetitive production of duplicate parts (which by the nature of their cutting process are usually interchangeable). It evolved from before lathes with the addition of the turret, which is an indexable tool holder that allows multiple cutting operations to exist performed, each with a different cutting tool, in easy, rapid succession, with no need for the operator to perform setup tasks in between (such as installing or uninstalling tools) nor to control the toolpath. (The latter is due to the toolpath being controlled by the machine, either in jig-like way via the mechanical limits placed on it by the turret's slide and stops, or via computer-directed servo mechanisms on CNC lathes.)[5]

There is a tremendous variety of turret lathe and capstan lathe designs, reflecting the variety of work that they exercise.

Gang-tool lathe [edit]

A gang-tool lathe is one that has a row of tools ready on its cross-slide, which is long and flat and is similar to a milling motorcar table. The idea is substantially the aforementioned equally with turret lathes: to fix multiple tools and and so easily alphabetize between them for each role-cut cycle. Instead of being rotary like a turret, the indexable tool group is linear.

Multispindle lathe [edit]

Multispindle lathes have more than than one spindle and automatic control (whether via cams or CNC). They are product machines specializing in high-book production. The smaller types are usually called screw machines, while the larger variants are ordinarily called automatic chucking machines, automated chuckers, or but chuckers. Screw machines usually work from bar stock, while chuckers automatically chuck up individual blanks from a magazine. Typical minimum profitable product lot size on a screw machine is in the thousands of parts due to the large setup time. Once prepare, a screw motorcar can rapidly and efficiently produce thousands of parts on a continuous basis with loftier accuracy, depression cycle time, and very niggling human being intervention. (The latter two points drive down the unit cost per interchangeable function much lower than could exist achieved without these machines.)

CNC lathe / CNC turning center [edit]

CNC lathe with milling capabilities

An example turned vase and view of the tool turret

Computer numerical controlled (CNC) lathes are chop-chop replacing the older product lathes (multispindle, etc.) due to their ease of setting, operation, repeatability and accurateness. A CNC Turning Lathe is a Calculator Controlled slice of machinery. It allows basic machining operations such as turning and drilling to be carried out equally on a conventional lathe. They are designed to use modernistic carbide tooling and fully use modern processes. The part may be designed and the tool paths programmed by the CAD/CAM process or manually by the programmer, and the resulting file uploaded to the machine, and in one case prepare and trialled the car volition continue to plough out parts under the occasional supervision of an operator.

The auto is controlled electronically via a computer menu style interface, the program may be modified and displayed at the machine, forth with a simulated view of the process. The setter/operator needs a high level of skill to perform the procedure. Nevertheless, the knowledge base is broader compared to the older product machines where intimate noesis of each machine was considered essential. These machines are often set up and operated by the same person, where the operator will supervise a small number of machines (jail cell).

The design of a CNC lathe varies with unlike manufacturers, merely they all take some common elements. The turret holds the tool holders and indexes them equally needed, the spindle holds the workpiece and there are slides that let the turret motion in multiple axes simultaneously. The machines are often totally enclosed, due in big part to occupational wellness and condom (OH&Due south) issues.

With rapid growth in this manufacture, different CNC lathe manufacturers use unlike user interfaces which sometimes makes it difficult for operators equally they have to be acquainted with them. With the advent of inexpensive computers, free operating systems such as Linux, and open source CNC software, the entry cost of CNC machines has plummeted.[ citation needed ]

CNC Horizontal Milling [edit]

CNC horizontal machining is performed using horizontally-configured lathes, machining centers, dull machines, or boring mills. The equipment used typically consists of rotating cylindrical cutters moving up and downwardly along five axes. These machines are capable of producing a diverseness of shapes, slots, holes, and details on a 3-dimensional office.[six]

CNC Vertical Milling [edit]

Vertically-oriented CNC machines employ cylindrical cutters on a vertical spindle axis to create plunge cuts and drilled holes, as well as custom shapes, slots, and details on three-dimensional parts. Equipment used in this blazon of milling includes vertical lathes, vertical machining centers, and 5-axis machines.[7]

Swiss-style lathe / Swiss turning center [edit]

A view inside the enclosure of a CNC Swiss-manner lathe/screw machine

A Swiss-style lathe is a specific pattern of lathe providing extreme accuracy (sometimes property tolerances as small equally a few tenths of a thousandth of an inch—a few micrometers). A Swiss-style lathe holds the workpiece with both a collet and a guide bushing. The collet sits behind the guide bushing, and the tools sit in front of the guide bushing, holding stationary on the Z centrality. To cut lengthwise along the part, the tools volition move in and the cloth itself will move back and forth along the Z centrality. This allows all the piece of work to exist done on the material nearly the guide bushing where it is more rigid, making them platonic for working on slender workpieces equally the part is held firmly with little take a chance of deflection or vibration occurring. This way of lathe is commonly used nether CNC command.

Most CNC Swiss-fashion lathes today use one or two main spindles plus one or 2 dorsum spindles (secondary spindles). The main spindle is used with the guide bushing for the main machining operations. The secondary spindle is located backside the part, aligned on the Z centrality. In simple operation it picks upwardly the role as information technology is cutting off, and accepts it for second operations, then ejects it into a bin, eliminating the need to have an operator manually modify each part, as is frequently the case with standard CNC turning centers. This makes them very efficient, as these machines are capable of fast cycle times, producing simple parts in ane cycle (i.e., no need for a second machine to finish the part with second operations), in as little as 10–xv seconds. This makes them platonic for large production runs of minor-bore parts.

Swiss-style Lathes and Live Tooling [edit]

As many Swiss lathes incorporate a secondary spindle, or 'sub-spindle', they also incorporate 'live tooling'. Live tools are rotary cut tools that are powered by a small motor independently of the spindle motor. Live tools increase the intricacy of components that can be manufactured by the Swiss lathe. For instance, automatically producing a function with a hole drilled perpendicular to the main axis (the axis of rotation of the spindles) is very economical with alive tooling, and similarly uneconomical if washed as a secondary operation afterwards machining past the Swiss lathe is consummate. A 'secondary operation' is a machining operation requiring a partially completed function to exist secured in a second machine to complete the manufacturing procedure. Generally, advanced CAD/CAM software uses live tools in improver to the main spindles so that almost parts that tin can be drawn by a CAD system tin can actually exist manufactured by the machines that the CAD/CAM software support.

Combination lathe / 3-in-1 machine [edit]

A combination lathe, oft known equally a 3-in-1 motorcar, introduces drilling or milling operations into the pattern of the lathe. These machines accept a milling column rising up higher up the lathe bed, and they use the wagon and topslide every bit the X and Y axes for the milling column. The iii-in-1 name comes from the thought of having a lathe, milling motorcar, and drill press all in one affordable machine tool. These are exclusive to the hobbyist and MRO markets, every bit they inevitably involve compromises in size, features, rigidity, and precision in guild to remain affordable. Yet, they run across the demand of their niche quite well, and are capable of high accuracy given enough fourth dimension and skill. They may be found in smaller, not-machine-oriented businesses where the occasional small function must exist machined, especially where the exacting tolerances of expensive toolroom machines, besides existence unaffordable, would exist overkill for the application from an engineering perspective.

Mini-lathe and micro-lathe [edit]

Mini-lathes and micro-lathes are miniature versions of a full general-purpose center lathe (engine lathe). They typically only handle piece of work of 3 to 7 in (76 to 178 mm) bore (in other words, one.five to 3.five in (38 to 89 mm) radius). They are small and affordable lathes for the home workshop or MRO shop. The same advantages and disadvantages apply to these machines as explained before regarding 3-in-1 machines.

Equally constitute elsewhere in English language-language orthography, there is variation in the styling of the prefixes in these machines' names. They are alternately styled as mini lathe, minilathe, and mini-lathe and as micro lathe, microlathe, and micro-lathe.

Brake lathe [edit]

A lathe specialized for the task of resurfacing restriction drums and discs in automotive or truck garages.

Wheel lathe [edit]

Wheel lathes are machines used to manufacture and resurface the wheels of railway cars. When wheels get worn or compromised from excessive use, this tool can be used to re-cut and recondition the wheel of the railroad train car. At that place are a number of dissimilar wheel lathes available including underfloor variations for resurfacing wheels that are withal attached to the rail auto, portable types that are hands transported for emergency cycle repairs, and CNC versions which utilize computer-based operating systems to complete the wheel repair.[viii]

Pit lathe [edit]

A lathe for big diameter, though short work, built over a recess in the floor to acknowledge the lower part of the workpiece thus allowing the toolrest to stand at the turner's waist meridian. An example is on brandish at the London Science Museum, Kensington.

Vertical lathe [edit]

For even larger diameter and heavier work, such as pressure level vessels or marine engines, the lathe is rotated so it takes the class of a turntable on which parts are placed. This orientation is less convenient for the operator, just makes it easier to support large parts. In the largest, the turntable is installed affluent with the floor, with the headstock recessed below, to facilitate loading and unloading workpieces.

Considering operator access is less of an issue for them, CNC vertical turning machines are more than popular than manual vertical lathes.

Oil land lathe [edit]

Specialised lathes for machining long workpieces such as segments of drill strings. Oil land lathes are equipped with large-bore hollow spindles, a second chuck on the opposite side of the headstock, and often outboard steadies for supporting long workpieces.

Feed mechanisms [edit]

Various feed mechanisms exist to feed cloth into a lathe at a divers charge per unit. The aim of these mechanisms is to automate function of the product process with the end goal of improving productivity.

Bar feeder [edit]

A bar feeder feeds a single piece of bar stock into the cutting automobile. As each part is machined, the cutting tool creates a final cut to separate the part from the bar stock, and the feeder continues to feed the bar for the side by side part, assuasive for continual operation of the machine. There are two types of bar feeds used in lathe machining: Hydrodynamic bar feeds, which rest the bar stock in a serial of channels whilst clamping down on the top and bottom of the bar, and hydrostatic bar feeds, which hold the bar stock in a feed tube using pressurized oil.[nine]

Bar loader [edit]

A bar loader is a variation on the bar feeder concept in that multiple pieces of bar stock may exist fed into a hopper, and the loader feeds each piece as necessary.

References [edit]

- ^ Nartov'southward biography (in Russian)

- ^ Naysmith, James (1841). "Remarks on the introduction of the slide principle in tools and machines employed in the product of machinery". In Buchnan, Robertson; Tredgold, Thomas; Rennie, George (eds.). Practical Essays on Mill Work and other Mechanism (third ed.). London: John Weale. p. 401.

I insinuate to the belatedly Henry Maudslay, engineer, of London, whose useful life was enthusiastically devoted to the grand object of improving our means of producing perfect workmanship and mechanism; to him we are certainly indebted for the slide residual, and consequently, to say the least, nosotros are indirectly so for the vast benefits which have resulted from the introduction of so powerful an agent in perfecting our machinery and mechanism generally.

- ^ Burghardt 1919, p. 118.

- ^ Parker, Dana T. Building Victory: Aircraft Manufacturing in the Los Angeles Area in World State of war II, p. 81, 123, Cypress, CA, 2013. ISBN 978-0-9897906-0-4.

- ^ "Horizontal CNC Milling Machines | Ardel Engineering". www.ardelengineering.com . Retrieved 2016-01-11 .

- ^ "Vertical CNC Milling Machines | Ardel Engineering". www.ardelengineering.com . Retrieved 2016-01-eleven .

- ^ "What Is a Wheel Lathe? (with picture)". wiseGEEK . Retrieved 2016-01-11 .

- ^ "Bar Feeds : Production Machining". www.productionmachining.com . Retrieved 2016-01-11 .

Bibliography [edit]

- Burghardt, Henry D. (1919), Motorcar Tool Operation, vol. 1 (1st ed.), New York, NY, USA: McGraw-Hill, LCCN 20026190.

External links [edit]

- Machine Tool Archive

- Medieval and Renaissance lathes

- The development of the lathe

- Bound pole lathe

- On ye art and mystery of Turning Archived 2009-12-25 at the Wayback Machine

- Video showing the gang tool concept

- Video showing a CNC spiral machine bike

- What is a CNC Turning Lathe?

- CNC Lathe Tool Turret

DOWNLOAD HERE

How to Cut a Gear on a Lathe UPDATED

Posted by: donnamereass.blogspot.com

How to Cut a Gear on a Lathe UPDATED. There are any How to Cut a Gear on a Lathe UPDATED in here.